|

Taizhou Yuanneng mould factory

|

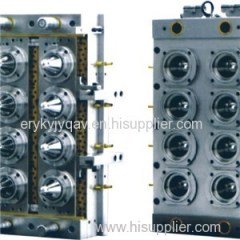

12 Cavities Hot Runner Needle Valve Preform Mould

| Place of Origin: | , China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

12 Cavities Hot Runner Needle Valve Preform Mould,PET Preform Mould

Mould Description:12 Cavities PET preform mould with hot runner.Shaping mode: Plastic Injection MouldProduct Material: SteelCavity quantity:12 cavitiesMain mould base :P20 steel (Nitrogen treatment, HRC 28-32 degree)Core (punch) and cavity:S136 (Vacuum quench treatment, HRC 43-52 degree)Screw neck (lip):S136Heating plate: H13 steel , Chinese standard manifold.Heating ring: ROTFIL from Italy.Temperature controller: PID voltage temperature controllerPreform mould configuration Adopted European mould structure: PET materials go into nozzle tip straightly to improve mould cycle time.Cooling system on cavity, core. If u require, we also design the cooling system on neck (slip).Preforms drop through injection machine central ejector automaticallyThe controller heat Individual cavities, runner and sprue. One Temperature zone control one point temperature. Double-locked, inter-changeable mould components;Usage life (guarantee):3,000,000 shots-5,000,000 shotsCertification: ISO9001Country of origin: ChinaBrand name: Yuan NengWarranty Period:one yearDelivery time:30-45 daysShipping Port:FOB Ningbo FOB ShanghaiMOQ: 1 set pet preform mouldPacking details: 1. Outside package: Standard wooden cases; 2. Inner package: Stretch waterproof film & Each Mold painted anti-rust oil. 3. Spare parts together with the mold shipment packed in wooden casesPayment T/T: 30%deposite, 70% balance after approval of all types of samples but before delivery.Mould features: 1)No cutting of valve gate is employed to reduce the labor cost 2)advanced hot runner system assures lower level of AA value 3)Reasonable-designed cold water channels increase cooling effect and shorten the cycle time.